Coupling is an important part of the transmission torque between the rotating shaft of the driving machine and the driven machine. The flexible diaphragm coupling can compensate for the inevitable radial, angular and axial offset between the two devices. According to the phenomenon of large channeling of the coupling of the oil pump unit, high bearing temperature and large vibration value, the coupling abnormal sound analysis has the following reasons:

Unit vibration

Pump inlet flow rate and pressure distribution is not uniform, non-rated conditions and various reasons caused by pump cavitation, impeller wear, etc., resulting in unit rotor mass imbalance, vibration exceeds the allowable value, pump critical speed and the natural frequency of the unit caused by resonance, etc., will produce strong vibration and noise.

Shafting parts wear

The wear of the coupling assembly and the loosening of the transmission bolt will cause the coupling to move, the wear of the pump body mouth ring, the bearing and the loosening of the lock nut at the end of the pump shaft will also cause the axial channeling of the pump to be large. These factors generally cause significant changes in various operational detection parameters

Unit alignment is poor

Due to the uneven subsidence of the unit foundation or the poor rigidity of the foundation, the levelness of the unit changes, resulting in the unit's coaxial excess. The foundation change will also cause the magnetic field center to shift, causing excessive shaft channeling and other electrical system imbalance, resulting in injection channeling, accompanied by vibration and noise unit fault diagnosis

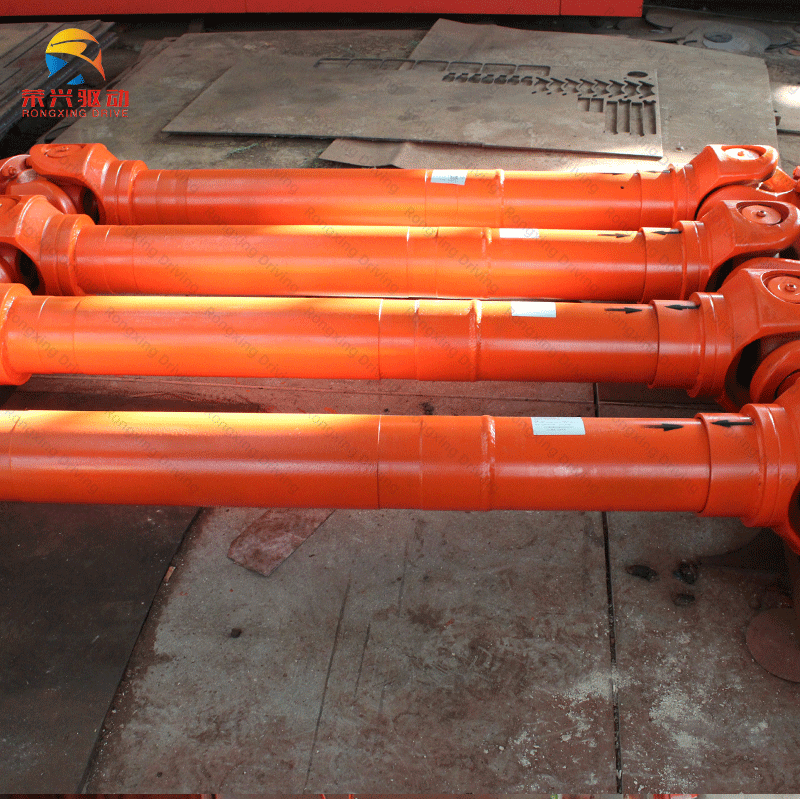

Coupling appearance inspection

In order to meet the requirements of dynamic balance, first mark the installation position of each part of the coupling. Then disassemble the flexible diaphragm coupling, remove the hexagonal screws, spacer sleeve and diaphragm group one by one, and remove the diaphragm from the spacer sleeve for inspection. Through inspection, it was found that there are wear marks on the inside of the two adjacent spacer sleeves, and the wear quality is about 3 grams compared with the standard parts, although it meets the requirements of the wear range.

Check unit shaft channeling and anchor screw inspection

Shaft channeling of unit is measured by dial indicator method. The inspection result is the left table +0.04mm, the right table -0.05mm, in line with the standard, 0.05mm requirements, check the pump unit all the foot bolts are in a tight state, no loose

Check the coaxiality of the unit

The alignment of the unit is checked by laser. Open the bearing box of the non-drive end of the pump and check all parts. Mainly check whether the lock nut at the end of the pump shaft is loose, whether the thrust bearing is abnormal wear, and the manual plate pump is not stuck, so that the pump side is not abnormal

After the appearance inspection and data analysis, it is considered that the pump side parameters of the oil pump unit are normal. The reasons for the high bearing temperature and abnormal noise may be caused by the excessive levelness of the motor end, the installation size of the coupling is too small, and the magnetic field center is offset.

During operation, the reason for the abnormal sound of the coupling is poor alignment of the shafting and high levelness of the non-driving end of the motor. The shaft system forms a lower opening, and the axial force on the pump side of the motor acts on the coupling, which causes deformation and periodic rebound of the diaphragm of the coupling. In addition, due to the lower drive side of the motor rotor caused by the forward movement, the magnetic field center occurs reciprocating offset, resulting in regular diaphragm impact, abnormal sound.

After the motor is adjusted, the coaxiality of the pump unit is tested, and the test result meets the error standard of 0.05mm. The unit is started, and the coupling abnormal sound, motor shaft channeling and vibration disappear after 3 hours of trial operation. The vibration data collected by the sensor of the unit is normal, the heating fault of the thrust bearing at the non-driving end of the pump is eliminated, and the unit runs smoothly.

The inspection of coaxiality, vibration and channeling is the routine work in the maintenance of the oil pump unit, which is the main parameter affecting the operation of the pump unit. The general risk check is only to adjust the coaxiality and the amount of channeling, and it is easy to ignore the change of the unit foundation and the levelness of the frame. The change of the foundation of the unit is easy to cause the displacement of the magnetic field center of the motor, resulting in the axial and reciprocating movement of the motor rotor. Accelerate the wear of coupling components, and then affect the working performance and service life of the coupling.

Contact: Spark Wang

Phone: 86-19932127135

E-mail: admin@rongxingcoupling.com

Add: North side of Planning 4th Road, Southern Industrial New Town, Jizhou District, Hengshui City, Hebei Province, China